Platinum, along with other platinum group metals (PGMs) such as palladium (Pd) and rhodium (Rh), is widely used in automotive catalytic converters (TWC), which reduce harmful emissions in vehicles. These metals are not consumed by the catalytic process but are instead used to facilitate chemical reactions that convert toxic gases (carbon monoxide, hydrocarbons, and nitrogen oxides) into less harmful substances. Over time, due to thermal wear and chemical erosion, small quantities of platinum are released from the catalytic converters into the surrounding environment. This is primarily in the form of fine particulates, which can then be deposited on road surfaces and road dust.

Road dusts in urban environments, where vehicular traffic is heavy, are recognized as a repository for these dispersed platinum particles. The concentration of platinum in road dust varies, but it has been observed that concentrations can range from tens to a few hundred parts per million (ppm) depending on traffic density and vehicle age. For example, platinum concentrations in road dust near major urban roadways have been reported to be as high as 500 ppm in some locations, with average concentrations of 100–200 ppm being typical in areas with high traffic volumes.

The accumulation of platinum on roadsides can also be influenced by the type of vehicle and the catalytic converter design. Older vehicles, which use less efficient catalytic converters, tend to emit higher amounts of platinum compared to newer models with more advanced emission control systems.

Road dust is a complex mixture of inorganic and organic materials, including:

Platinum from catalytic converters typically exists in the form of platinum oxides (PtO, PtO2), which may be adsorbed onto particulate matter or incorporated into ceramic substrates. Thus, the platinum is not only embedded in fine road dust particles but may also be present in the form of nanoscale deposits on the surfaces of other components.

While platinum recovery from road dust is possible, several technical challenges make it a complex process:

The recovery of platinum from roadside environments requires a series of steps that focus on isolating platinum from other components of the dust and then extracting it in a form that is suitable for reuse. Below are the key steps involved in platinum recovery:

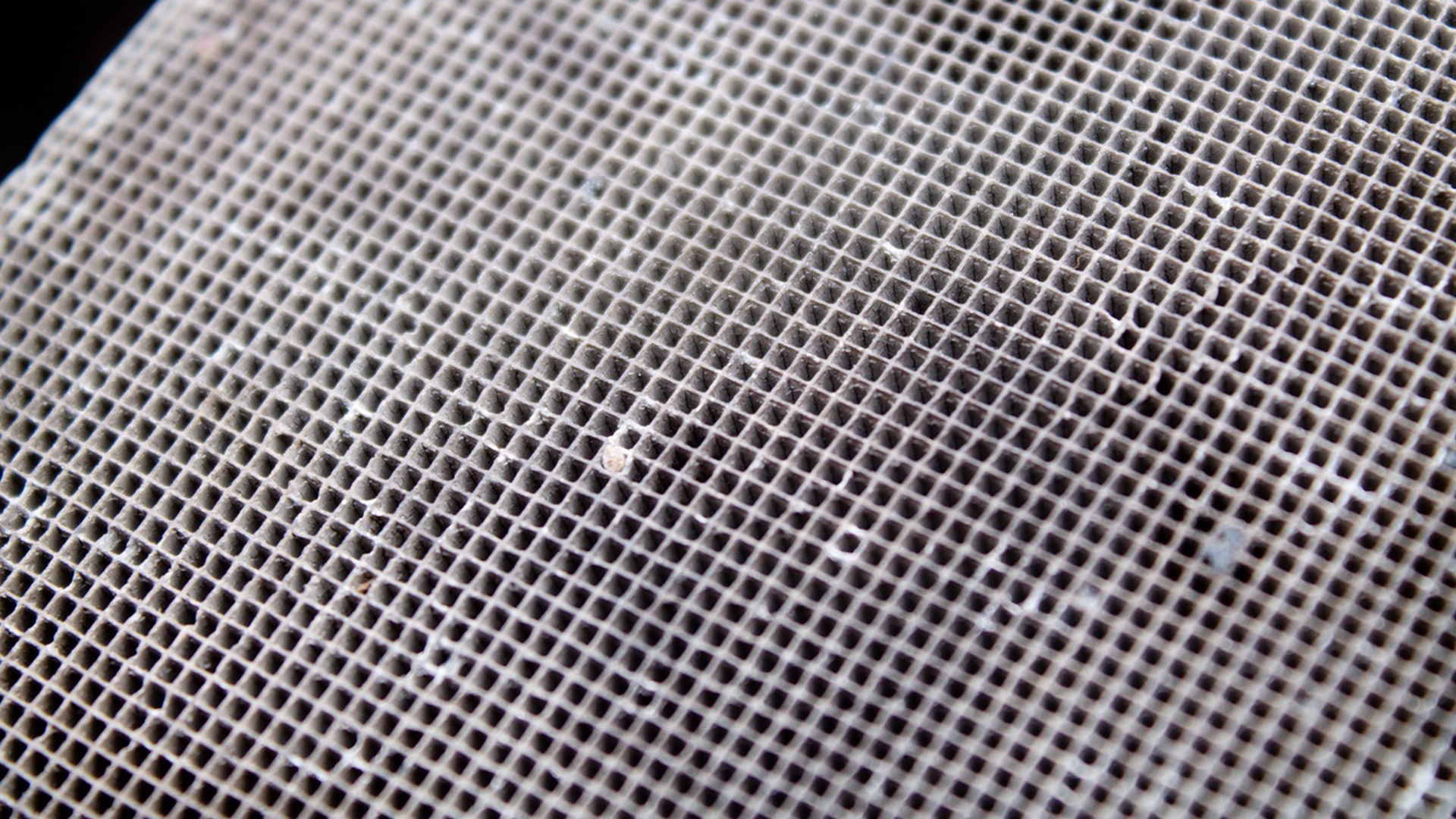

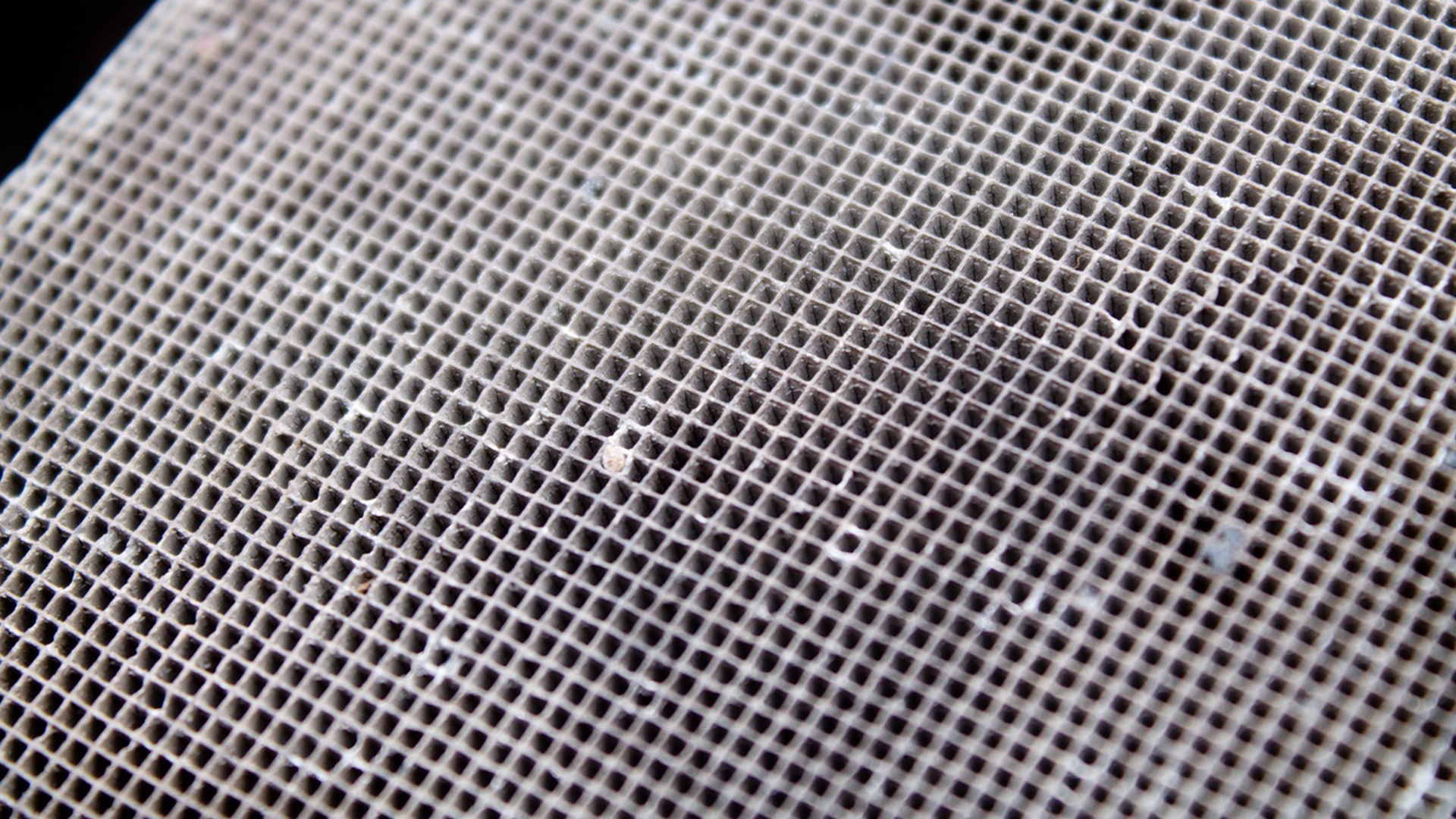

The first step in the recovery process is the collection of road dust. This is typically done through mechanical means such as street sweepers, vacuum systems, or using specialized filters to capture dust from urban roadways. The volume of dust collected will be large, and for substantial platinum recovery, vast amounts of road dust need to be processed.

Once the road dust is collected, the next challenge is to separate platinum-enriched particles (often adhering to alumina or other oxide-based materials) from the rest of the dust matrix. This step may involve several methods:

To recover platinum from the isolated platinum-enriched particles, chemical leaching techniques can be employed. These methods involve using acid or base solutions to dissolve platinum from its solid matrix and make it available for further processing:

Once platinum has been dissolved into a liquid phase, it can be recovered by reducing it back to its metallic state. This is typically achieved by using reducing agents like hydrogen gas or by adding chemical reducers like sodium borohydride. The platinum can then be precipitated from the solution as fine metallic particles or flakes. The reduced platinum is often purified by washing and drying, and it can be further processed for reuse in catalytic converters, fuel cells, or other industrial applications.

The cost of recovering platinum from roadside dust presents a significant challenge, as the concentration of platinum in road dust is typically low, making large-scale recovery economically unfeasible unless processing methods are scaled up efficiently. The complexity of the dust matrix, which contains a mixture of materials, further complicates the recovery process. In order for platinum recovery to be economically viable, techniques used in mining and recycling industries would need to be adapted to the specific characteristics of roadside dust.

On the other hand, there are considerable environmental benefits to recovering platinum from road dust. This process can reduce the need for platinum mining, which is energy-intensive and environmentally damaging. Mining activities often lead to ecosystem disruption, water contamination, and the release of greenhouse gases. By recycling platinum from urban environments, these negative environmental impacts can be minimized, contributing to sustainability and resource conservation.

However, there are regulatory and safety concerns that need to be addressed in the recovery process, particularly with respect to the contamination of road dust by other harmful heavy metals, such as lead and cadmium. It is crucial that any recovery methods adhere to strict environmental safety protocols to prevent hazardous by-products from being released into the environment, particularly in urban areas where dust can easily be inhaled by humans or animals. Therefore, ensuring the safe handling and processing of road dust is a key component of any recovery initiative

The recovery of platinum from roadside dust is technically feasible but faces several challenges, including low platinum concentrations, the complexity of the dust matrix, and the high cost of recovery processes. However, with advances in separation technologies, chemical leaching, and recovery methods, the process could become more economically viable in the future. Furthermore, the environmental benefits of recovering platinum from roadside dust, reducing reliance on virgin mining, and promoting recycling make this an attractive area for research and development. A successful large-scale recovery process would help mitigate the environmental impacts of platinum mining while providing a valuable source of platinum for industrial applications.