Silver has played a pivotal role in human civilization for over 6,000 years. Its historical significance is matched by its growing importance in today's world, where it finds applications in electronics, electrical equipment, photography, medicine, and wastewater treatment. Despite being more affordable than gold or platinum, silver is not as abundant in the earth's crust. It is typically found in ores mixed with gold, copper, lead, and zinc.

In 2014, global silver production reached 877.5 million ounces, but the availability of natural silver resources is on the decline. This scarcity has led to increased production costs, even though the market price for silver has dropped due to its expanded use across various industries. With silver's increasing demand, there is a pressing concern about its environmental impact, particularly its toxicity to marine life, microorganisms, and humans. This has highlighted the urgent need for effective recovery methods to handle silver from industrial waste and spent sources.

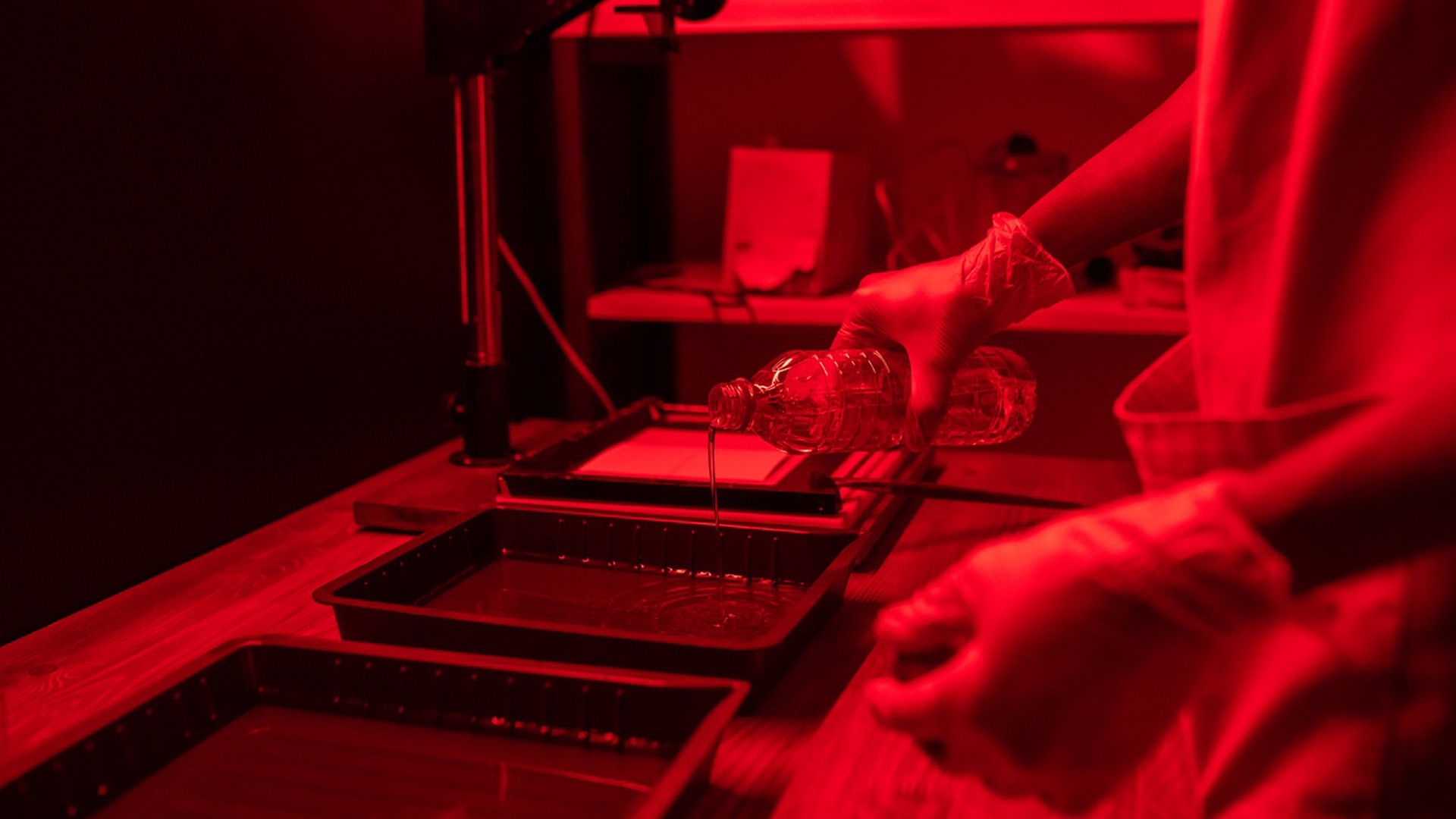

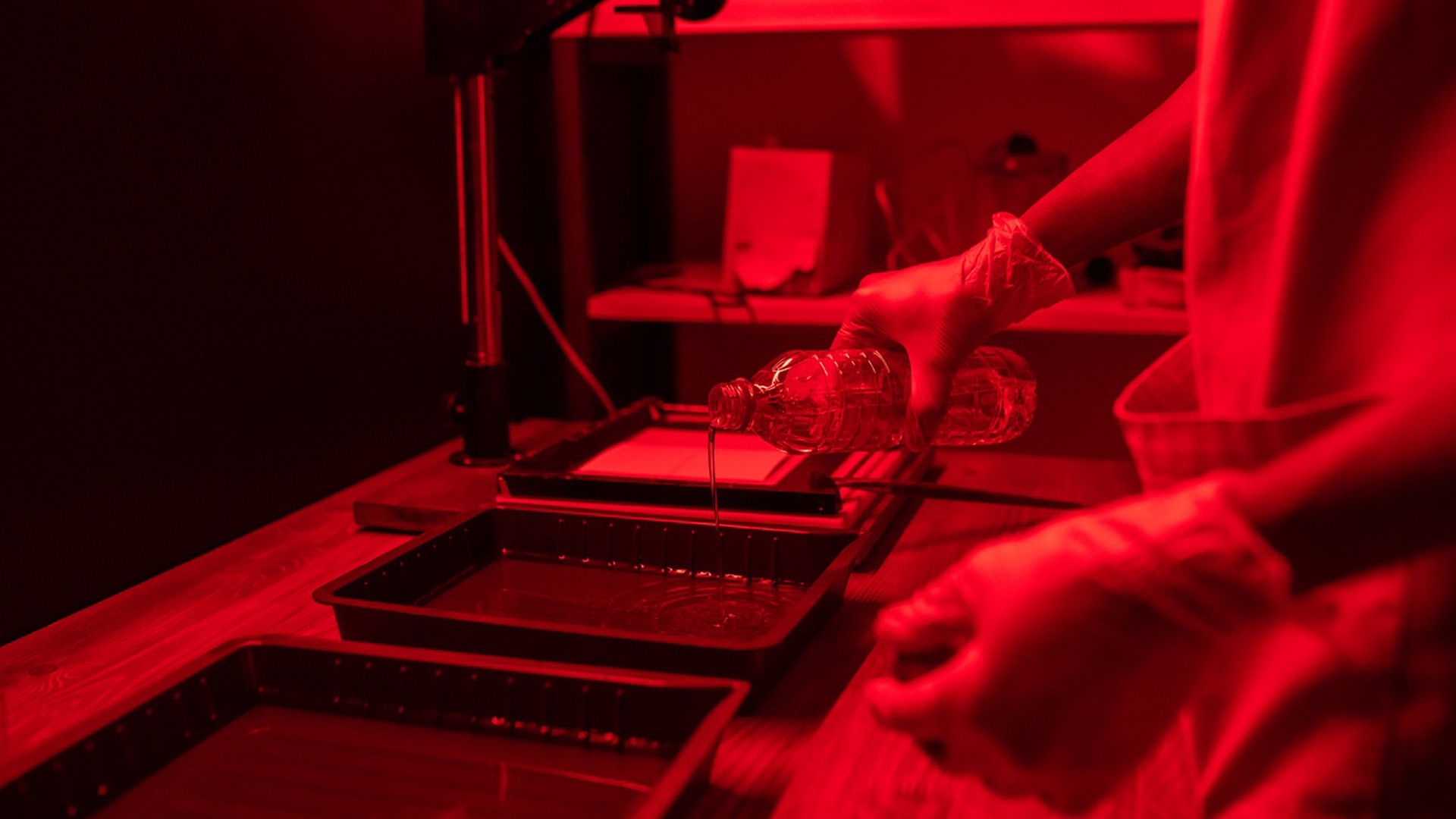

The recycling of silver-containing materials involves processing a wide range of sources, including ores, electronic materials, waste jewelry, catalysts, and more. The complexity of this process arises from the different physical and chemical characteristics of each source. Initially, materials undergo pretreatment, such as washing, crushing, and physical separation, to concentrate the silver content. These methods yield low-purity metals, which are then processed using recovery techniques like leaching, adsorption, or chemical reduction to produce crude silver. Finally, refining processes increase the purity of silver to over 99.9%.

This process involves a series of leaches using acids or bases to extract silver. The metal is separated and concentrated through techniques like precipitation, solvent extraction, and ion exchange. The final recovery is achieved using methods like electro-winning, cementation, or crystallization.

An emerging and environmentally friendly method, bio-hydrometallurgy uses microorganisms to extract metals from materials. Bacteria such as Acidithiobacillus ferrooxidans and Chromobacterium violaceum can mobilize silver from ores and electronic waste. Techniques like bio-oxidation and bio-sorption are employed for extracting silver.

Leaching dissolves silver from various materials using agents like cyanide, ferricyanide, thiourea, and thiosulphate. Each leaching agent has its advantages in terms of efficiency, cost, and environmental impact. For example:

List of substituted leaching agents for silver leaching from primary and secondary sources are presented in Table 1

Table 1. List of silver leaching agents from primary and secondary sources. | ||

Leaching agents |

Efficiency (%) |

References |

Thiosulphate, EDTA, Cu(II), ammonia |

100 |

|

Thiosulphate |

99 |

|

Sodium thiosulphate, ammonia and sodium sulfite |

97–99 |

|

Thiourea, sulfuric acid and ultrasound |

98.6 |

|

Nitric acid |

96.1 |

|

Thiourea |

95.6 |

|

Thiosulphate and copper sulfate |

95.1 |

|

Ammonium chloride |

95 |

|

Hydrochloric acid and calcium chloride |

92 |

|

Ammonium thiocyanate + oxygen pressure |

88 |

|

Sodium cyanide and hydrogen peroxide |

87 |

|

Sulfuric acid and hydrogen peroxide |

85 |

|

Sodium chloride, HCl and H2O2 |

82 |

|

Hydrochloric acid–hydrogen peroxide |

80 |

|

Chloride |

60–80 |

|

Acidic thiourea-ferric iron |

71.36 |

|

Ferric-EDTA-thiosulphate |

70 |

|

Thiourea and Fe3+ |

50 |

|

Bromination |

50 |

|

Ferricyanide and sodium cyanide |

Unknown |

|

Acidothiourea |

Unknown |

|

Copper–ammonia-thiosulphate |

Unknown |

|

Aqueous ozone |

Unknown |

|

Ferric sulfate and sulfuric acid |

Unknown |

|

Thiosulphate, ammonia and cupric ion |

Unknown |

|

FeCl3-HCl and Fe2(SO4)3-H2SO4 |

Unknown |

|

Thiourea, sulfuric acid and ferric ions (Acidothioureation) |

Unknown |

|

Ammoniacal, bromine, iodine and hydrogen peroxide |

Unknown |

|

Hydrochloric acid and sodium chloride |

Unknown |

|

Oxygenated aqueous ammonia |

Unknown |

|

Thiocarbamide |

Unknown |

|

Acidic ferric chloride and copper chloride |

Unknown |

|

Acidithiobacillus ferrooxidans (A. ferrooxidans) |

98 |

|

Mesophilic bacteria |

Unknown |

|

Cyanogenic Chromobacterium violaceum, Pseudomonas fluorescens, and P. plecoglossicida |

Unknown |

|

Silver recycling is a complex but necessary endeavor, driven by both economic and environmental imperatives. Understanding the toxicity of silver and exploring innovative recovery methods are essential steps toward achieving effective and sustainable silver recycling. By advancing research and adopting safer technologies, we can better manage these precious resources and mitigate their environmental impact.

At Phoenix Refining, we are committed to leading the way in silver recycling with cutting-edge solutions designed to maximize recovery while minimizing environmental harm. Our state-of-the-art technologies and expert team ensure that we efficiently recover silver from both primary and secondary sources, adhering to the highest standards of safety and sustainability. By partnering with us, you can contribute to a greener future and make the most out of your silver resources. Visit Phoenix Refining to learn more about our innovative recycling solutions and how we can support your sustainability goals.